NOUVEM Recipe Management Software Solutions

This week at NOUVEM we have released a new version of our Recipe Management Software, below is a quick outline;

NOUVEM Food Processing software is a suite of software modules specifically designed for food manufacturers. One of our software modules deals with manufacturing using a recipe, or bill of materials (BOM).

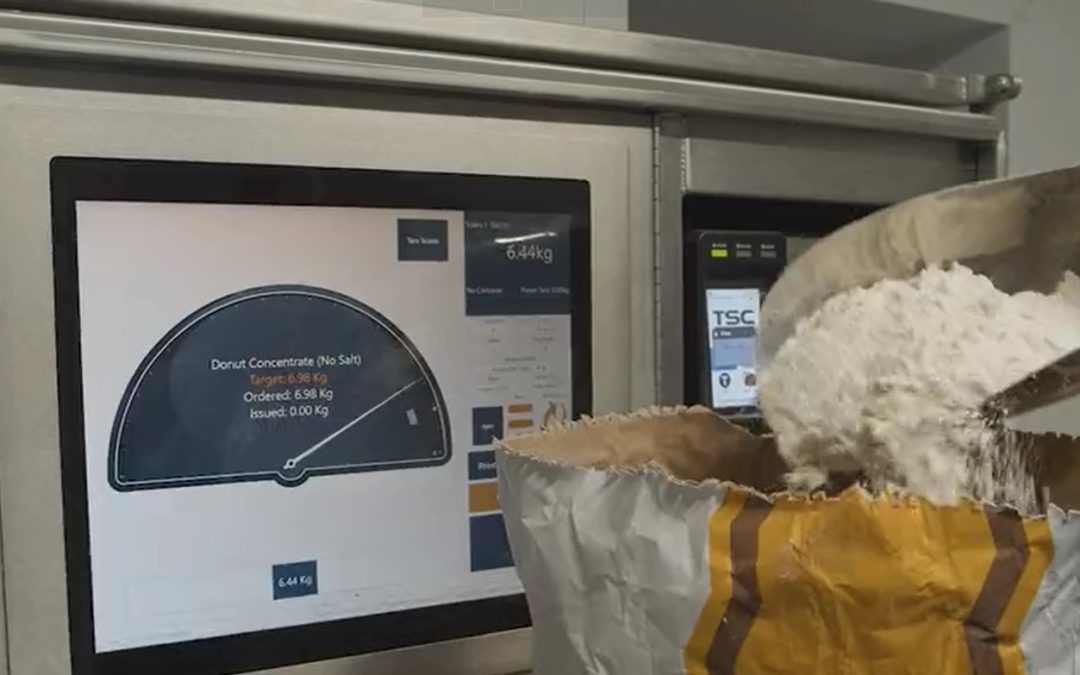

In its simplest form, the operator on the factory floor will select (using a touchscreen computer) a product to be made, specify the quantity to be made and NOUVEM will then present the quantities required to complete this task. Depending on how these recipes are setup, the operator will weigh out each ingredient and the touchscreen computer will implement controls on tolerances allowed per ingredient. Ingredients can be scanned, manually booked, weighed or back flushed into these production runs and all traceability is recorded, based in logic agreed with the client.

In a more complex configuration, sales orders, stock and projections can be pulled together into a planning module where the planner will determine quantities to be manufactured. Once plans are activated, jobs will appear on touchscreen terminals around the factory, in the location where these jobs are prepared. For example; the sauce jobs might appear on the sauce room terminals and the packing jobs on the packing terminals. Each recipe or bill of materials can have unlimited sub-assemblies and these jobs can be automatically calculated and aggregated across all production jobs. This approach leads to high efficiencies in manufacturing and gives the planner the necessary information and tools to complete the planning process efficiently.

As well as helping planners and operators, NOUVEM food processing software will track all ingredients, packaging and labour used. NOUVEM recipe processing software allows you to cost your jobs against multiple models. In a simple example, your ingredients may have a cost allocated to them and this cost will iterate through sub-assemblies to finished products before the products are manufactured. In a more complex model NOUVEM can capture the real time costs and present an actual cost using real costs and quantities.

Paperless recipe formulation systems and ingredient management software

- Central management of all products and raw materials.

- Provide mass balance of ingredients – see where everything went.

- Reduce and track your waste.

- Reduce product giveaway.

- Increase product consistency.

- Display SOPs on factory terminals.

- HACCP and CCP checks in real time – no paper involved.

- Track labour costs and processing times.

- Stock Control including shelf-life management.

- Impress auditors and customers with fast mass balance and product recall reporting.

- Reduce paperwork overhead on staff – operators, managers, Planners and QC all love NOUVEM as it gives them the tools to do their jobs more effectively.